Creating a 1:1 replacement for High-Pressure Sodium (HPS) lamps in LED horticulture lighting involves ensuring that the LED system provides equivalent or better light output, spectrum, and energy efficiency while meeting the specific needs of the plants being grown. Here’s a step-by-step guide to achieve this:

1. Understand HPS Output

- HPS lamps typically provide:

- PPF (Photosynthetic Photon Flux): ~1.2–1.8 µmol/J (efficiency).

- Total Light Output: ~600–1500 µmol/s (depending on wattage, e.g., 600W or 1000W HPS).

- Spectrum: Heavy in yellow/red wavelengths (580–700 nm), which are effective for flowering and fruiting stages.

- HPS lamps typically provide:

- Measure the existing HPS system’s light output (PPFD, spectrum, and coverage) to establish a baseline.

2. Match the PPF and PPFD

- Calculate the total PPF (Photosynthetic Photon Flux) of your HPS system. For example:

- A 600W HPS lamp with 1.5 µmol/J efficiency produces:

600W × 1.5 µmol/J = 900 µmol/s PPF.

- A 600W HPS lamp with 1.5 µmol/J efficiency produces:

- Calculate the total PPF (Photosynthetic Photon Flux) of your HPS system. For example:

- Choose an LED system with equivalent or higher PPF. Modern LEDs often achieve 2.5–3.0 µmol/J, so a 600W HPS can be replaced with a 300–400W LED system:

- 400W LED × 2.5 µmol/J = 1000 µmol/s PPF.

- Choose an LED system with equivalent or higher PPF. Modern LEDs often achieve 2.5–3.0 µmol/J, so a 600W HPS can be replaced with a 300–400W LED system:

- Ensure the PPFD (Photosynthetic Photon Flux Density) at the canopy level matches or exceeds the HPS system (e.g., 600–1000 µmol/m²/s for flowering).

3. Match the Spectrum

- HPS lamps are strong in the red/orange spectrum (600–700 nm), which is critical for flowering and fruiting.

- Choose an LED system with a spectrum tailored to your plants’ growth stage:

- Vegetative Growth: Higher blue (400–500 nm) for compact, leafy growth.

- Flowering/Fruiting: Higher red (600–700 nm) to mimic HPS output.

- Choose an LED system with a spectrum tailored to your plants’ growth stage:

- Full-spectrum LEDs with adjustable red/blue ratios are ideal for versatility.

4. Ensure Proper Coverage

- HPS lamps have a wide light spread, so the LED system must provide uniform coverage.

- Use LED fixtures with proper optics (e.g., 90° or 120° lenses) to match the coverage area of your HPS lamps.

- Adjust the hanging height of the LEDs to achieve the desired PPFD uniformity.

5. Consider Heat Management

- HPS lamps emit significant radiant heat, which may affect the growing environment.

- LEDs produce less heat, so you may need to adjust your climate control (e.g., heating or ventilation) to maintain optimal temperatures.

6. Energy Efficiency and Cost Savings

- LEDs are more energy-efficient than HPS lamps, often reducing energy consumption by 40–50%.

- Calculate the energy savings and return on investment (ROI) based on your electricity costs and LED system lifespan (typically 50,000–100,000 hours).

7. Test and Validate

- Before fully replacing HPS with LEDs, conduct a side-by-side comparison:

- Measure growth rates, yield, and plant health under both lighting systems.

- Adjust light intensity, spectrum, and photoperiod as needed.

- Before fully replacing HPS with LEDs, conduct a side-by-side comparison:

Example Replacement:

- HPS System: 1000W HPS lamp producing for 1800 µmol/s PPF.

- LED Replacement: 1000W LED fixture producing 3600 µmol/s PPF with a DEEP RED spectrum solution, one 1000W LED can double the lighting level of 1000W HPS, under this context, the replacement is economic worthwhile in electronic consumption

By following these steps, you can create a 1:1 replacement for HPS in LED horticulture lighting while potentially improving plant growth and reducing energy costs.

SZNUMBER Example Led Solution for HPS replacement:

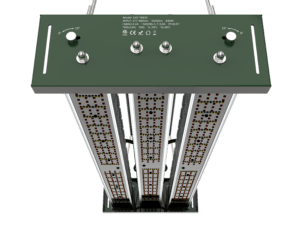

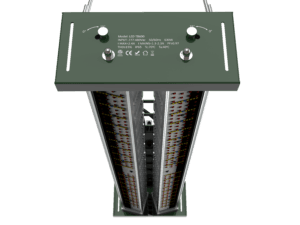

SZNUMBER conducted a series of LED options for HPS replacement, taking the LED TB series for example

The LED TB600 is up to 50% energy-saving for HPS retrofit, features a flexible beam angle of up to 150° with engineering-design tempered glass design for UV/IR spectrum to enhance crop quality and yield.

Available in 800W and 1000W models with 3-bar configurations for higher lighting level application demand.